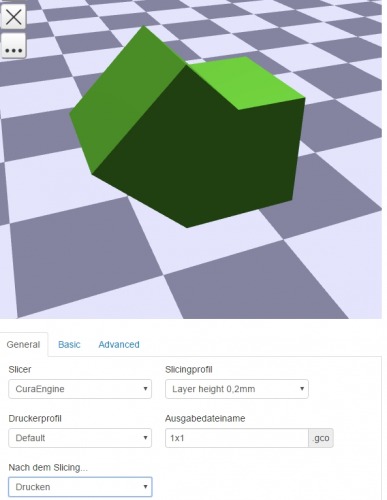

This is the technique most commonly used for 3D printing. We will now see how to address the third point. When printing in 3D, you must always make sure this loss of quality stays below your minimal requirements.īelow, we will assume that the first two criteria are met, and that by now you are able to produce solid objects with correct dimensions. In any case, some loss of quality of your model will unavoidably occur during the process. The conversion of your models into G-Code can be easy and automatic, or you can also do it manually, with total control over the output. G-code has dozens of different dialects, each machine or vendor usually using its own. Most of them will only understand a machine language called G-Code. No 3D printing or CNC milling system can take FreeCAD files directly. Controlling the degradation or loss of accuracy.

One millimeter will be one millimeter in real-life. Making sure of the dimensions of your objects.The Part Workbench also contains a Check Geometry tool that is handy to check further for possible defects. We saw in earlier chapters that FreeCAD helps you a lot in that regard, and that the Part Design Workbench will notify you if an operation will prevent your model from remaining solid. Real-world objects are solid, the 3D model must be solid too. Making sure that your 3D objects are solid.

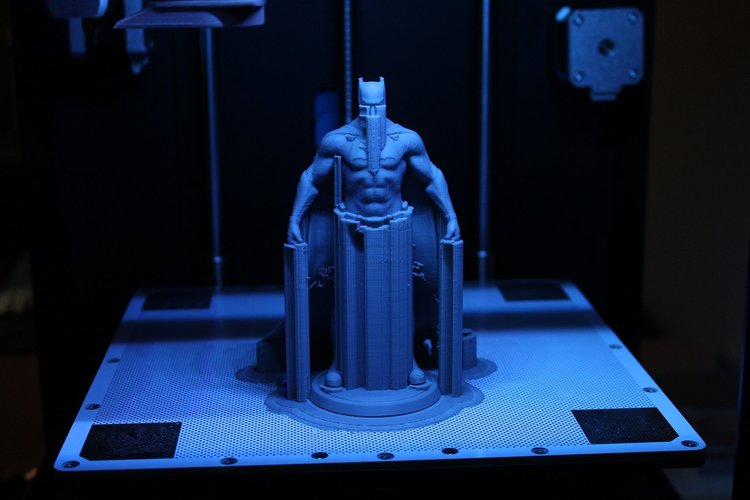

If you have been cautious while modeling, most of the difficulty you might encounter when printing your model in 3D has already been avoided. This chapter will show you how to get your models ready to send to these machines. These can be designed in FreeCAD, and then made real by different ways, such as communicated to other people who will then build them, or, more and more frequently, sent directly to a 3D printer or a CNC mill. One of the main uses of FreeCAD is to produce real-world objects.

0 kommentar(er)

0 kommentar(er)